Comprehensive Web-Based Production ERP System

Our advanced web-based ERP system offers a robust suite of features designed to streamline and enhance your production processes

Vision ERP transforms your manufacturing operations with streamlined processes and enhanced efficiency, ensuring precision and productivity at every step.

Our advanced web-based ERP system offers a robust suite of features designed to streamline and enhance your production processes

Ensure precise material use and reduce error

Optimize budgeting and inventory management.

Improve resource utilization and minimize waste.

Align production with forecasted needs for timely delivery.

Automated time tracking reduces errors, ensuring precise payroll and labor cost management.

Real-time monitoring of attendance and activities identifies inefficiencies and optimizes workforce allocation.Historical attendance data aids in accurate forecasting and efficient shift scheduling.

Seamless integration with payroll software simplifies calculations and reduces administrative tasks.

Automated adherence to labor laws and regulations minimizes legal risks and ensures proper working hour management.

Detailed attendance reports provide valuable analytics for better decision-making and performance improvement.

Biometric and RFID authentication prevent buddy punching and unauthorized access, protecting productivity.

Automated tracking lowers administrative costs and reduces operational inefficiencies.

Transparent tracking of work hours encourages punctuality and responsibility.

Automated procurement processes ensure timely and accurate sourcing of materials, supporting uninterrupted production.

Centralized tools for evaluating and managing suppliers lead to better material quality and reliability.

Detailed analysis of procurement data helps identify cost-saving opportunities and secure the best prices for production materials.

Advanced analytics on procurement trends support precise forecasting of material needs, reducing waste and shortages.

Automation speeds up the procurement cycle, ensuring that materials are available when needed for production.

Integration with production schedules ensures materials are ordered and delivered in sync with manufacturing requirements.

Automated compliance checks and risk assessments ensure adherence to regulations and minimize procurement-related risks.

Real-time tracking of procurement activities provides visibility into material sourcing and enhances decision-making.

Automated purchase order creation and management ensure timely procurement of materials, aligning with production schedules.

Real-time tracking of material purchases and stock levels prevents shortages and overstock, maintaining optimal inventory.

Automated comparison of supplier quotes helps secure the best prices for materials, reducing production costs.

Detailed reports on material purchases provide insights into usage patterns and supplier performance, supporting better financial planning.

Centralized supplier information and communication tools enhance coordination and negotiation with vendors, ensuring timely material delivery.

Automated record-keeping ensures compliance with procurement policies and regulations, providing a clear audit trail for material transactions.

Real-time visibility into material purchase orders and inventory levels improves accountability and decision-making in production.

Compatibility with production software ensures that material procurement aligns perfectly with manufacturing needs and schedules.

Get instant updates on materials, accessories, fabric, and consumables for precise stock management and timely production. Maintain ideal inventory levels and prevent overstock or shortages across all inventory types, enhancing operational efficiency.

Seamlessly manage reordering with automated alerts, ensuring consistent availability of materials, accessories, and consumables.

Achieve clear, real-time visibility into all inventory categories, reducing discrepancies and supporting accurate production planning.

Use predictive analytics to accurately forecast needs for materials, fabric, and consumables, minimizing waste and ensuring adequate supply.

Monitor work-in-progress inventory to streamline production flow and reduce delays, ensuring smoother operations.

Track and manage by-products efficiently to reduce waste and maximize resource utilization.

Analyze material and consumable wastage to identify inefficiencies and optimize inventory usage.

Automated record-keeping makes inventory audits straightforward, ensuring accuracy and regulatory compliance.

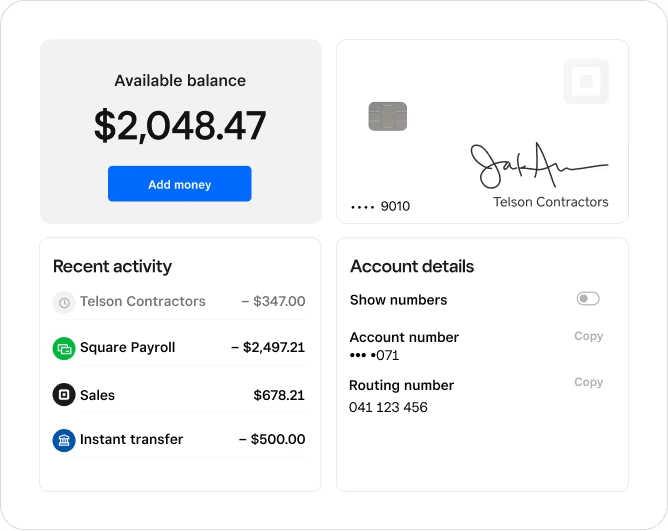

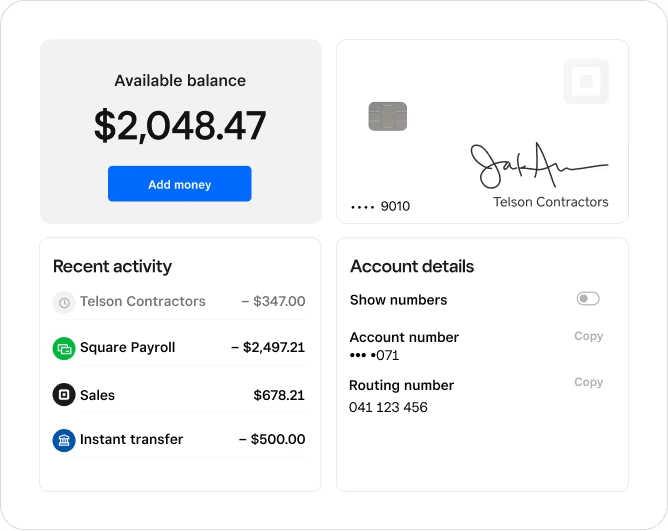

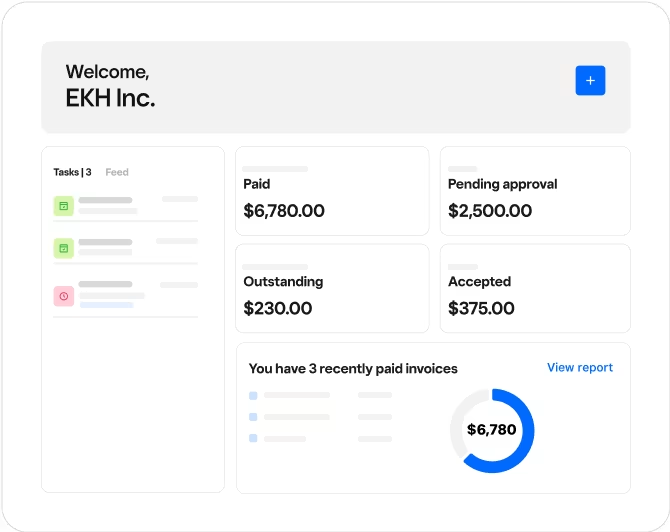

Monitor and allocate costs for materials, labor, and production processes to ensure precise expense management and budgeting.

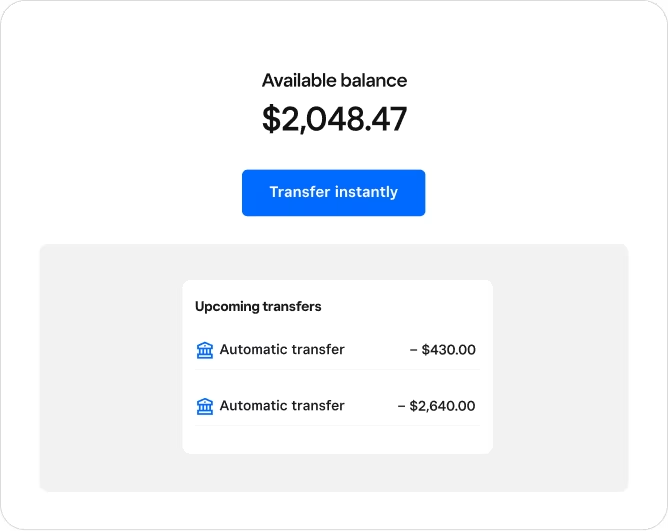

Manage and automate payments based on output and performance, streamlining compensation for contractors and employees.

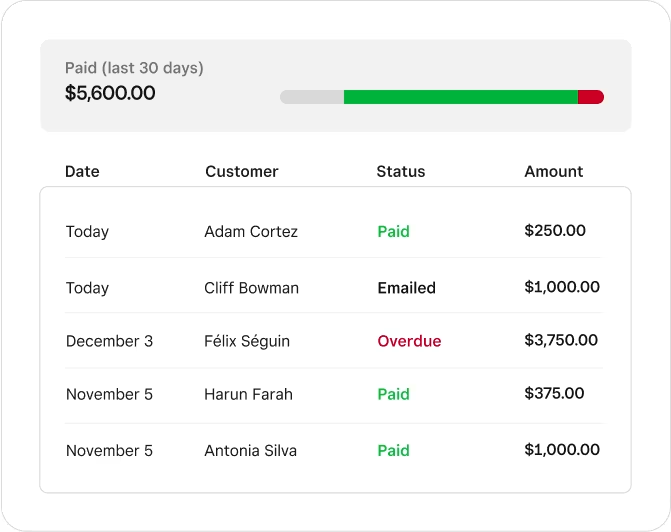

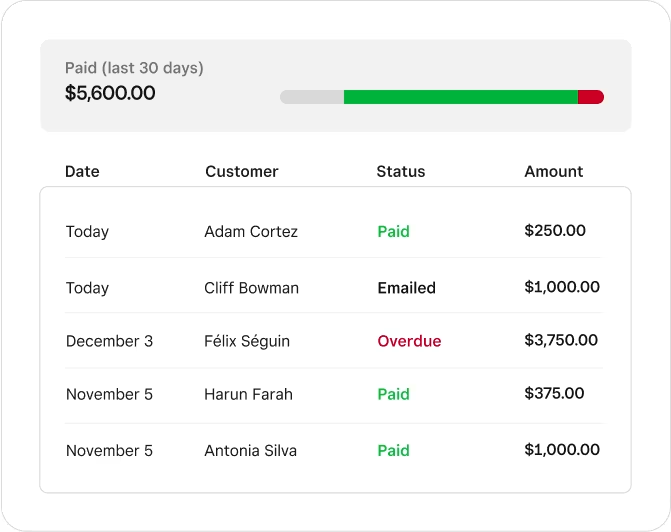

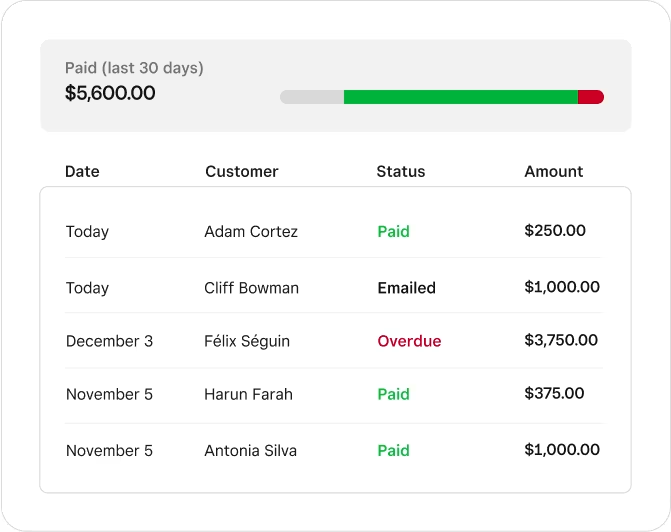

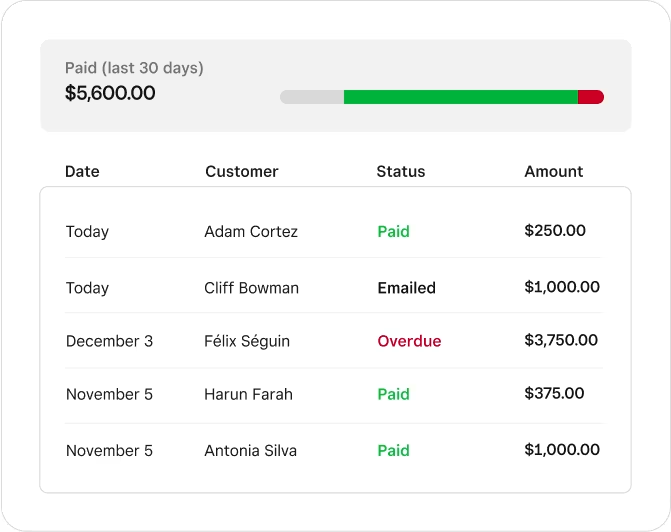

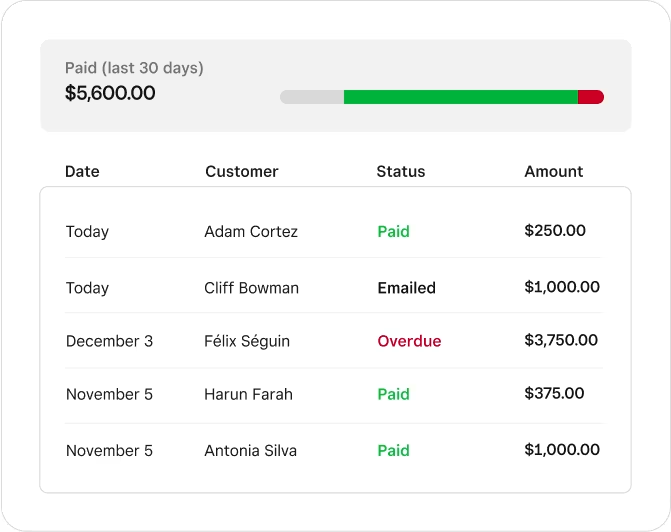

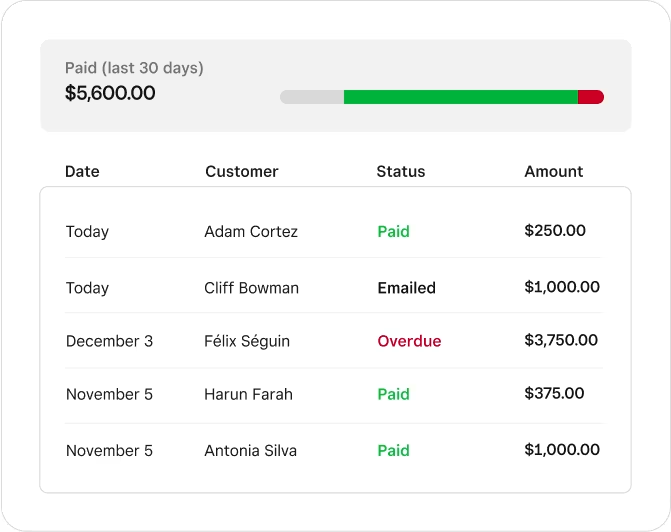

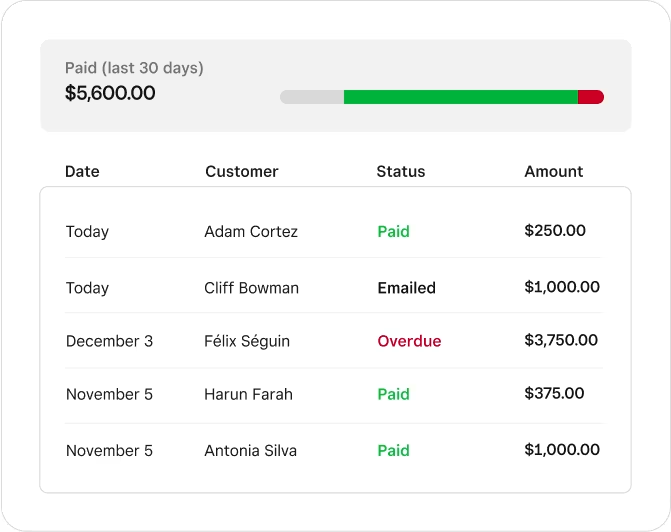

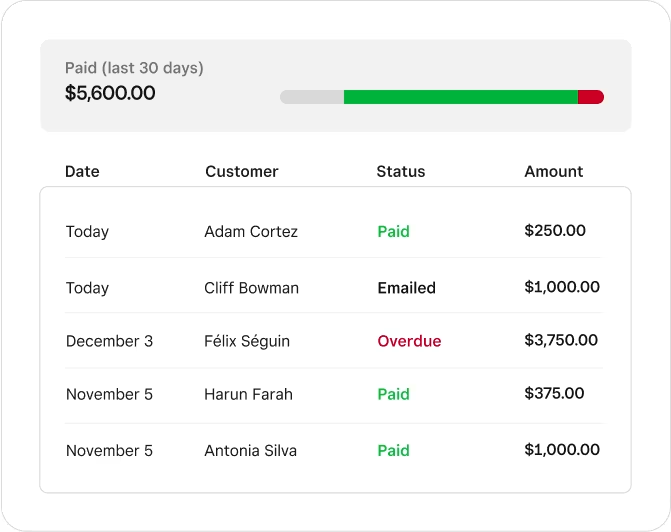

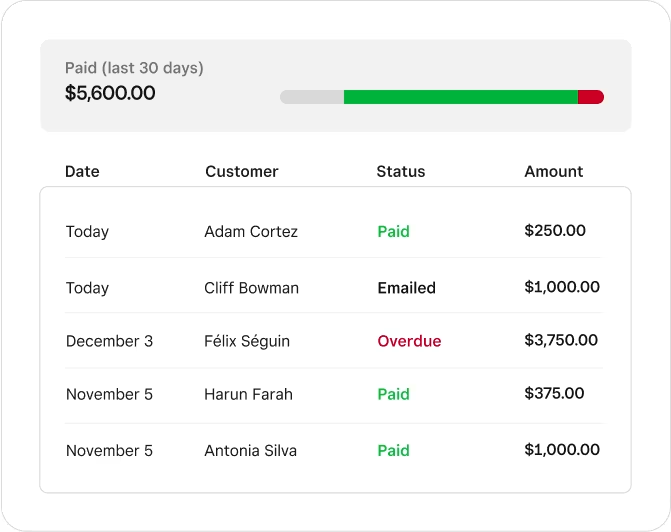

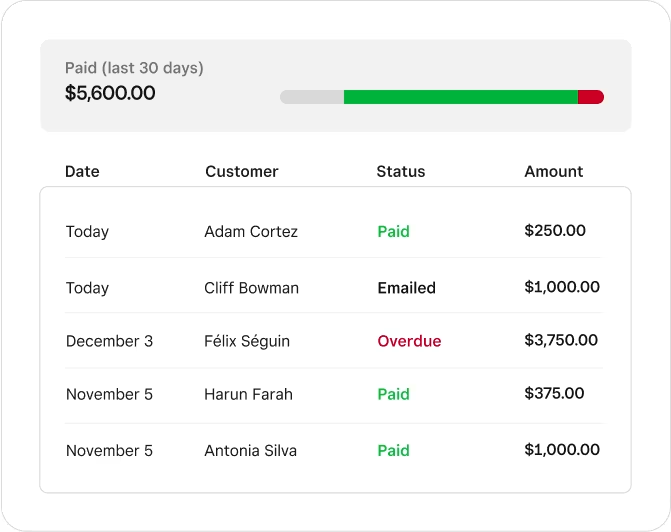

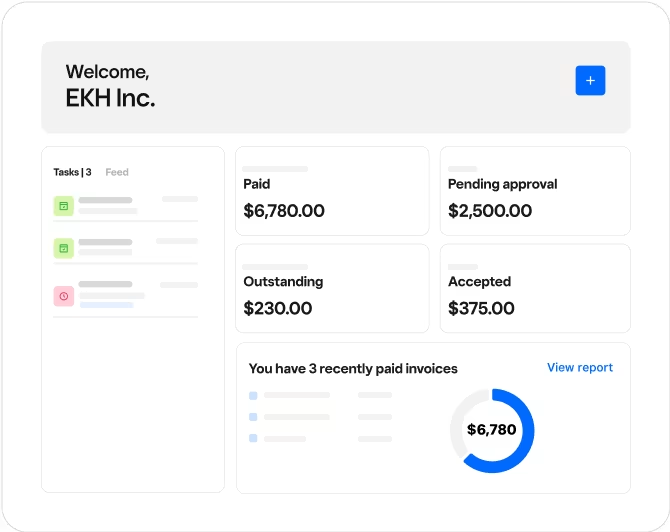

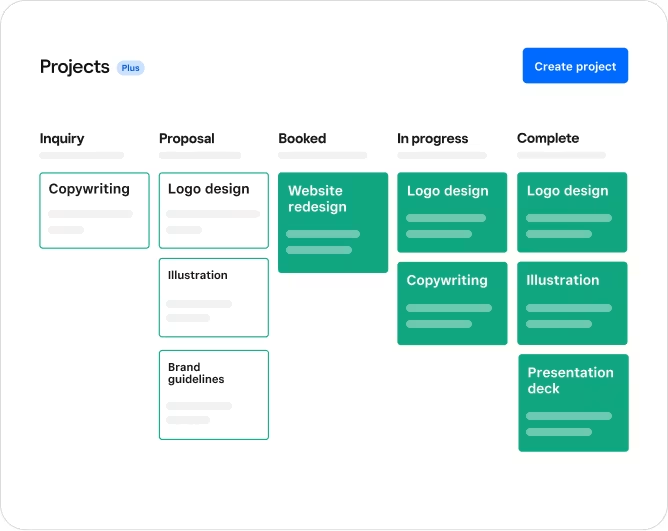

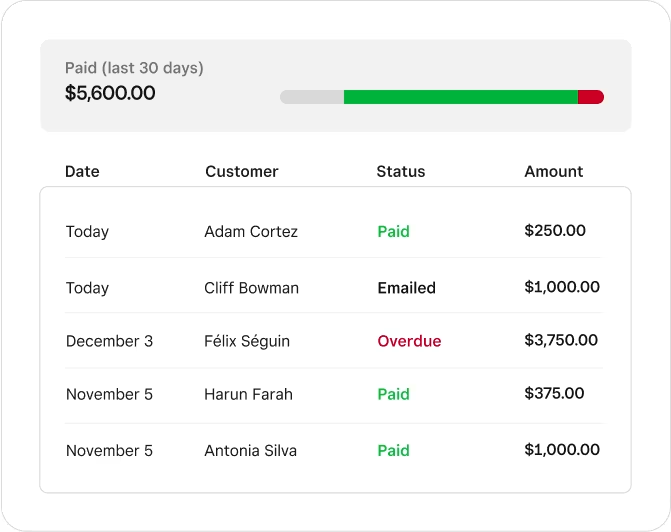

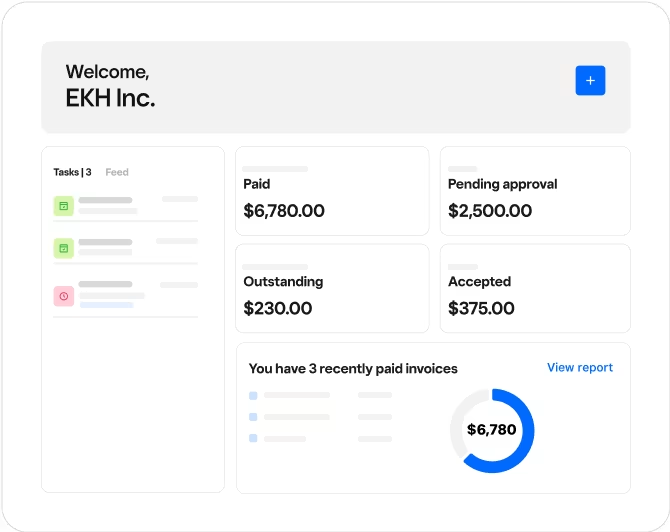

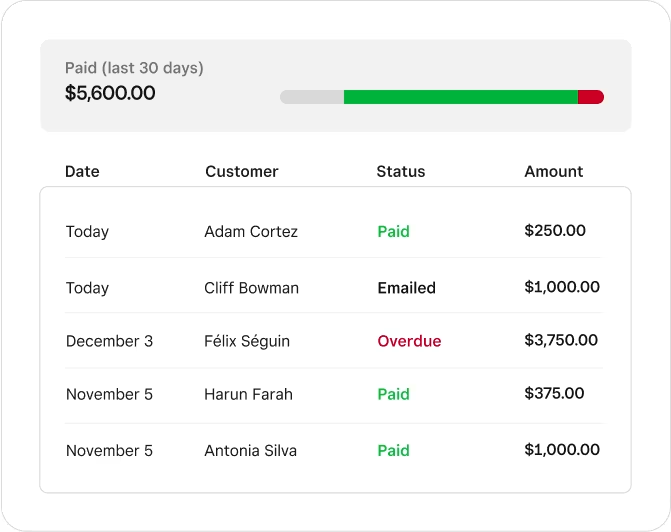

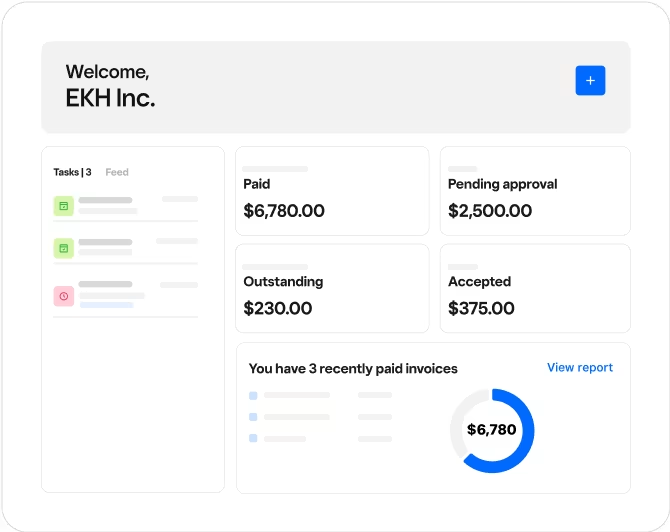

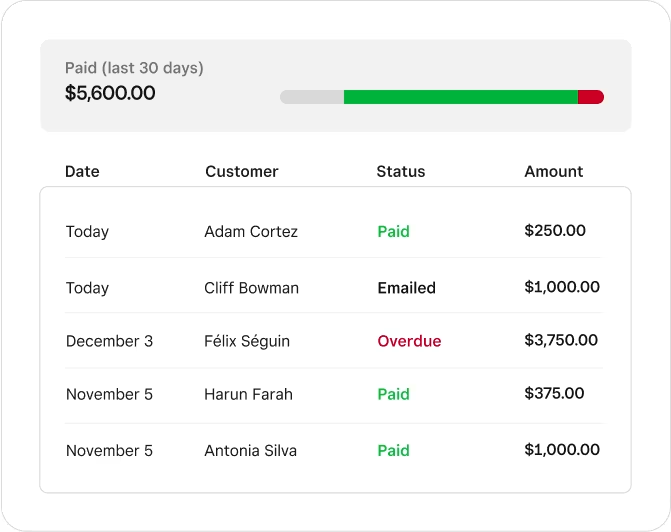

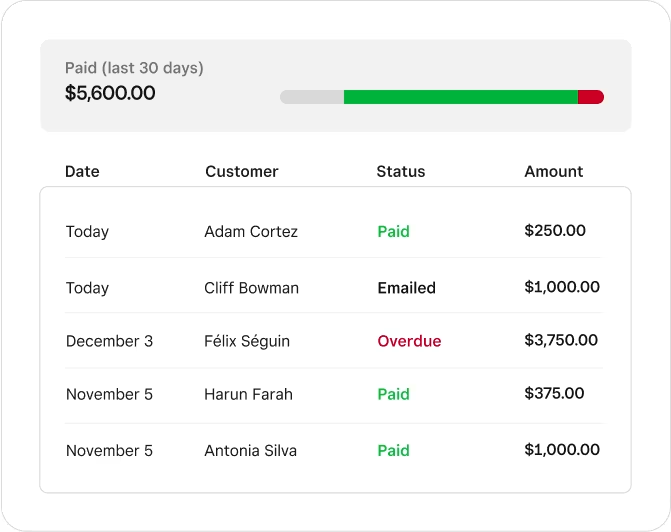

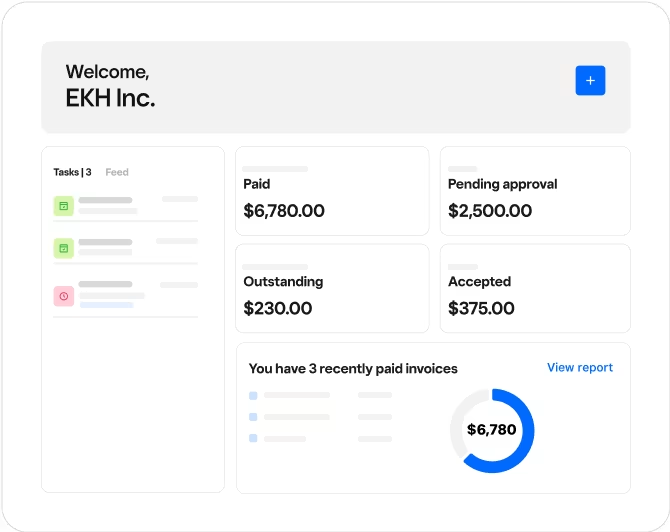

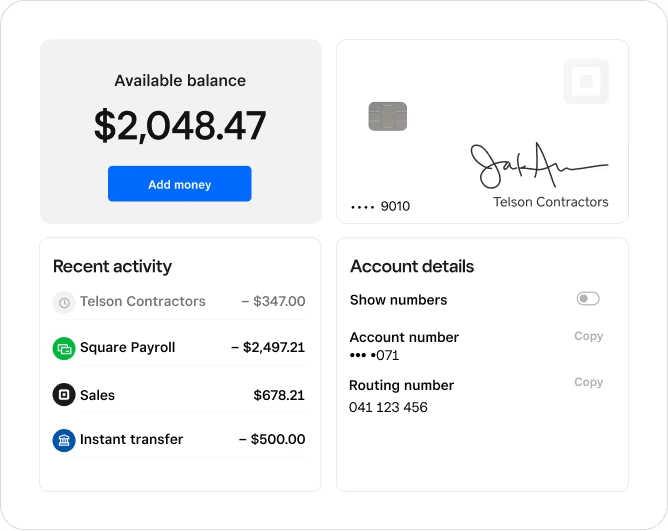

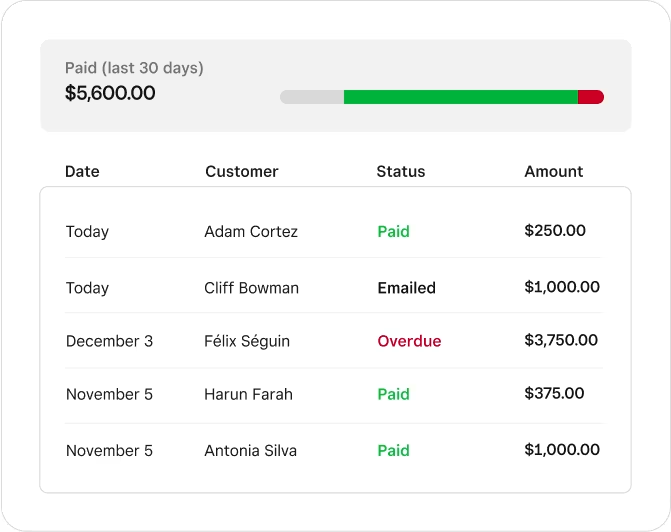

Access up-to-the-minute reports on production costs, revenues, and profitability, supporting better financial oversight and decision-making.

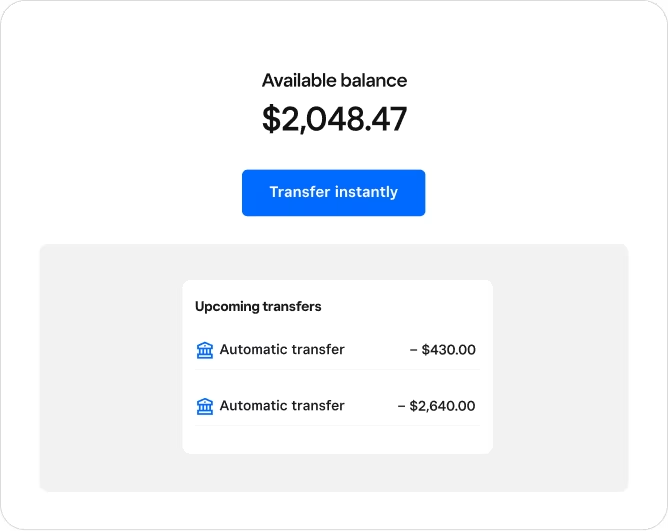

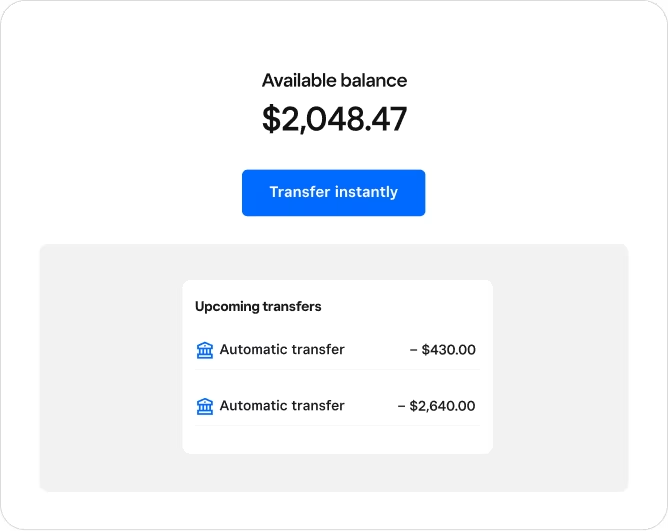

Track production expenses against budgets in real time to prevent overruns and ensure financial control.

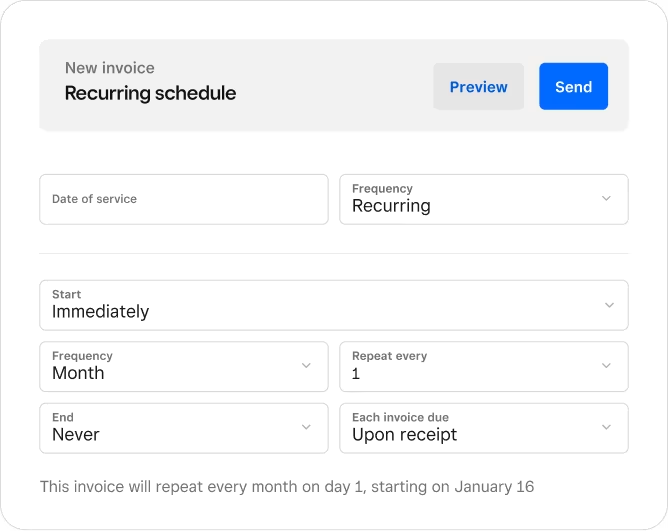

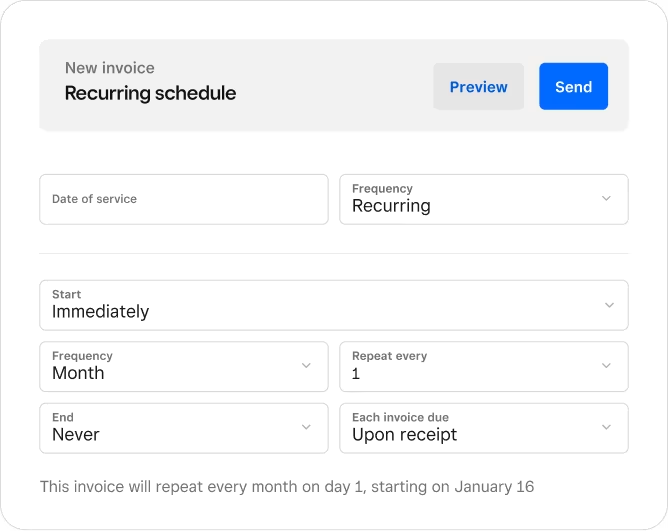

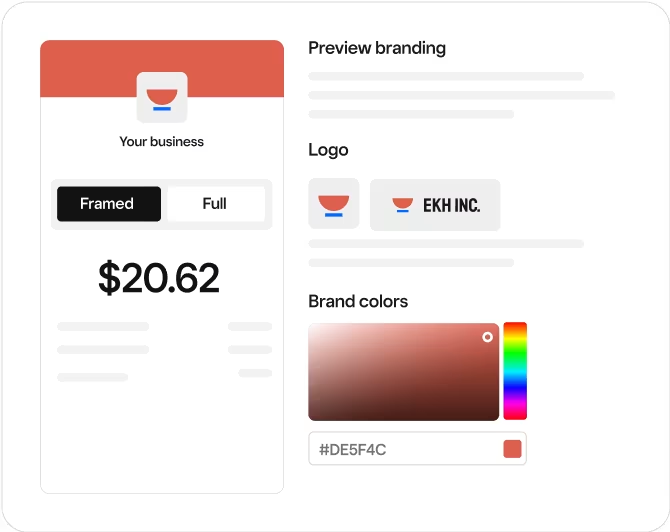

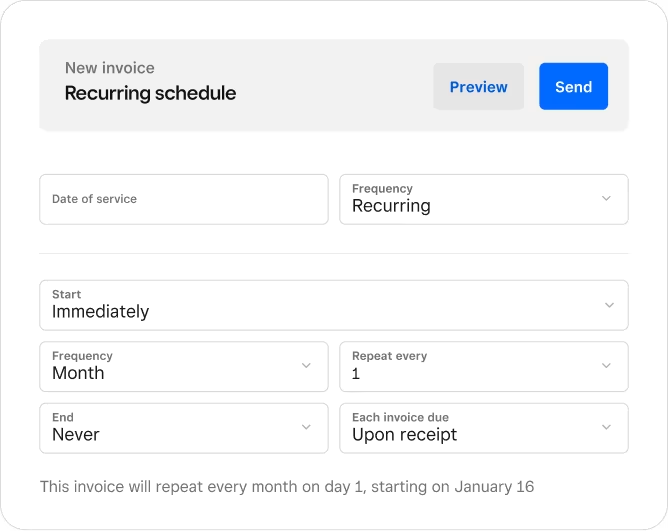

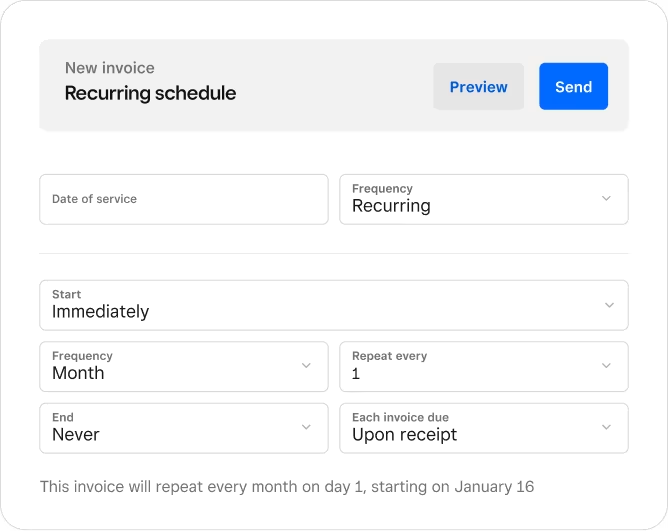

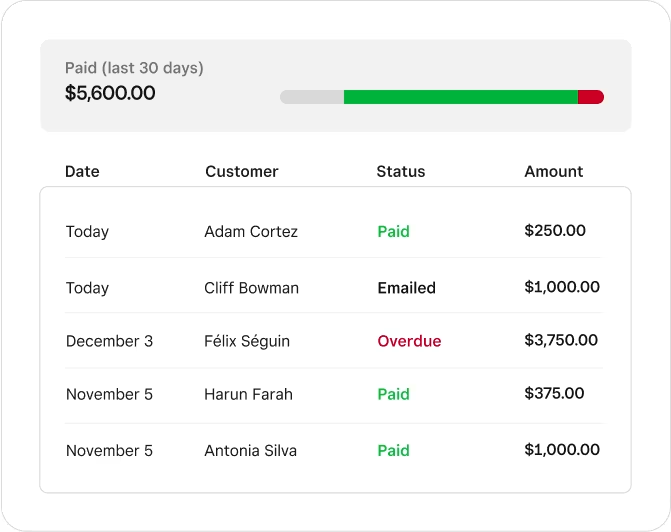

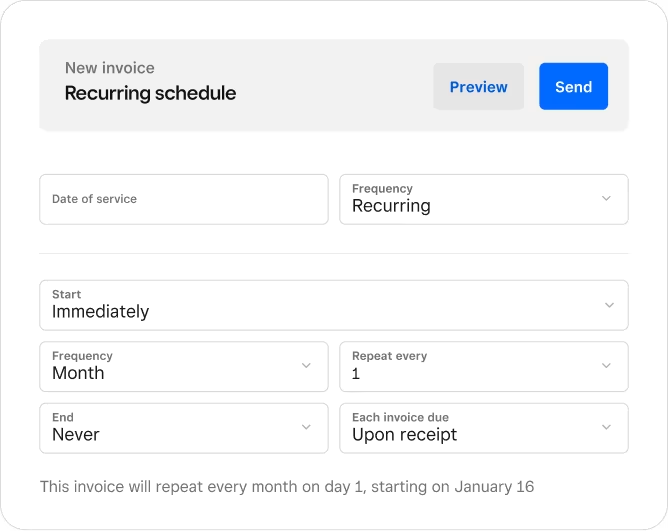

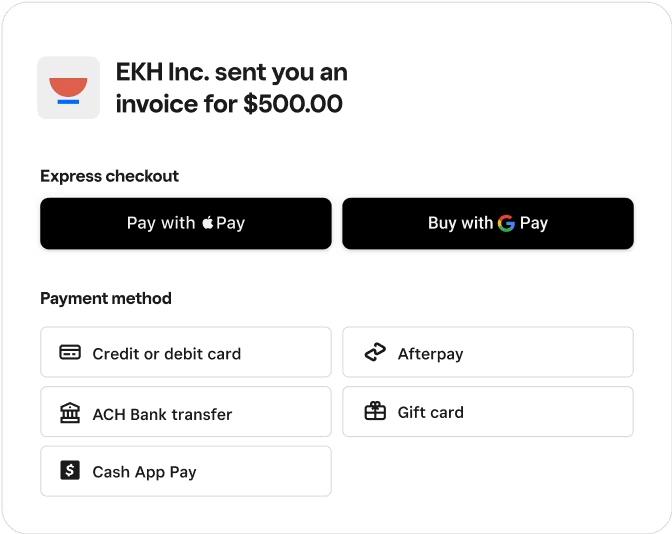

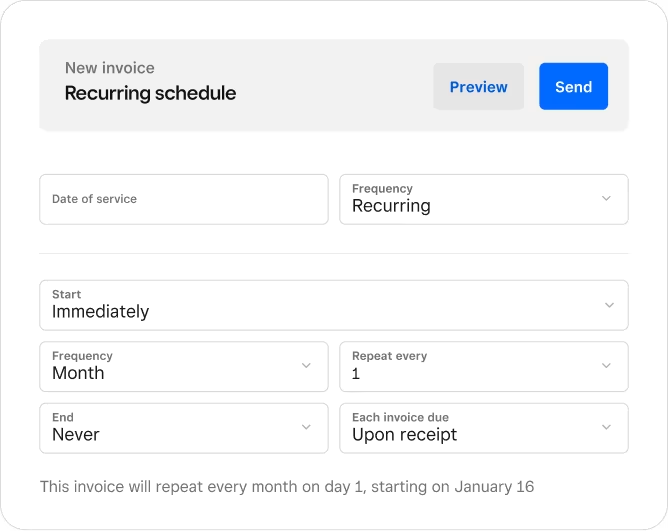

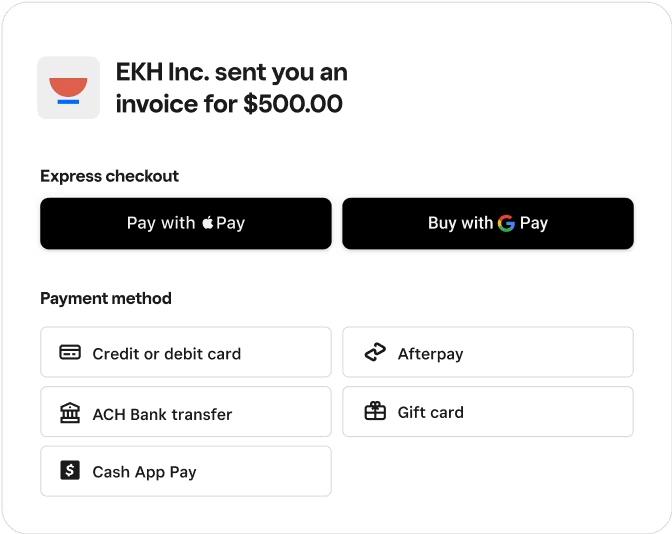

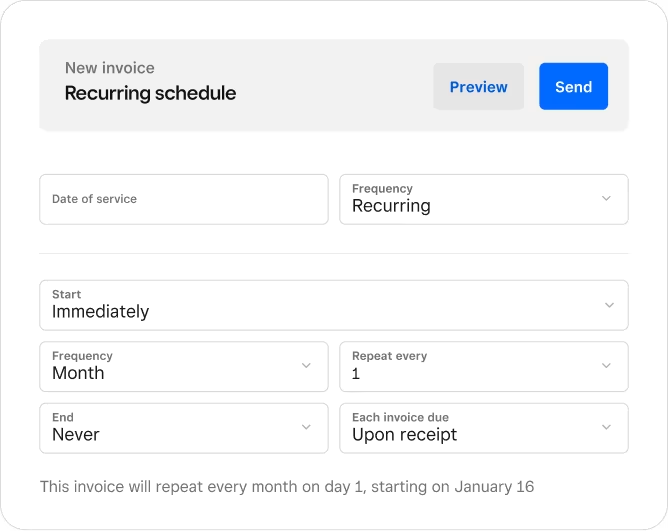

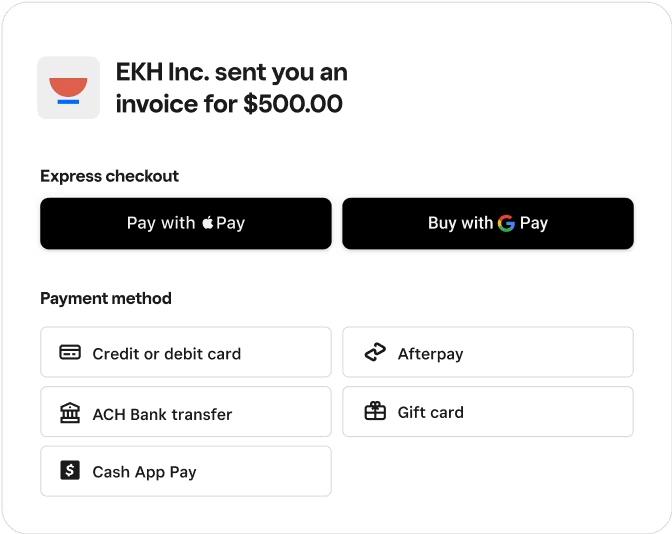

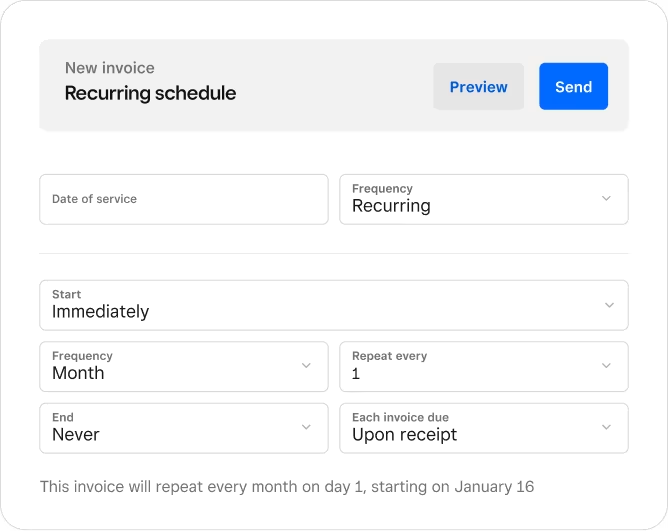

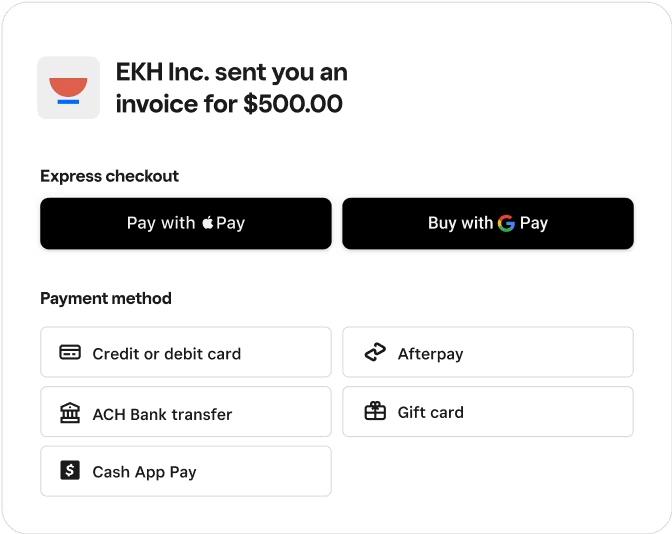

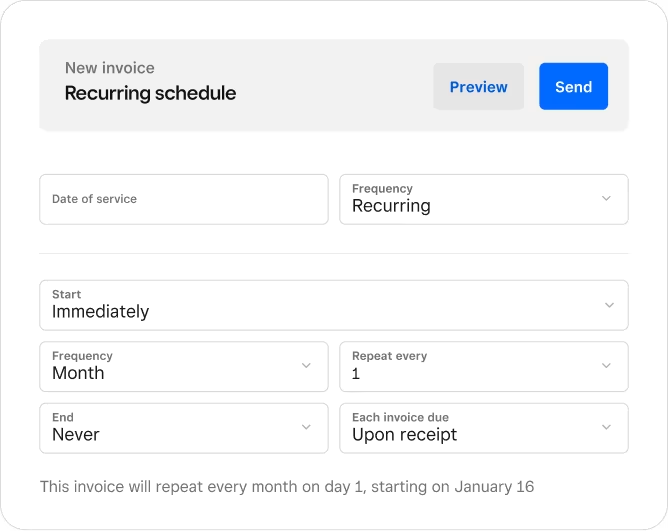

Simplify invoice processing with automation, reducing administrative tasks and improving accuracy in billing and payments.

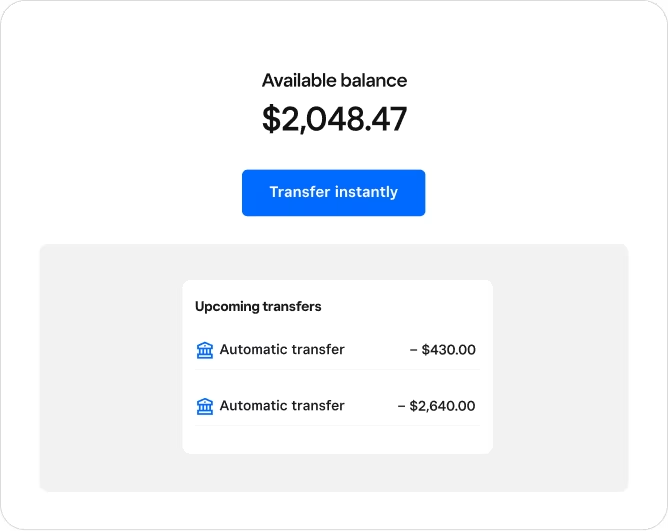

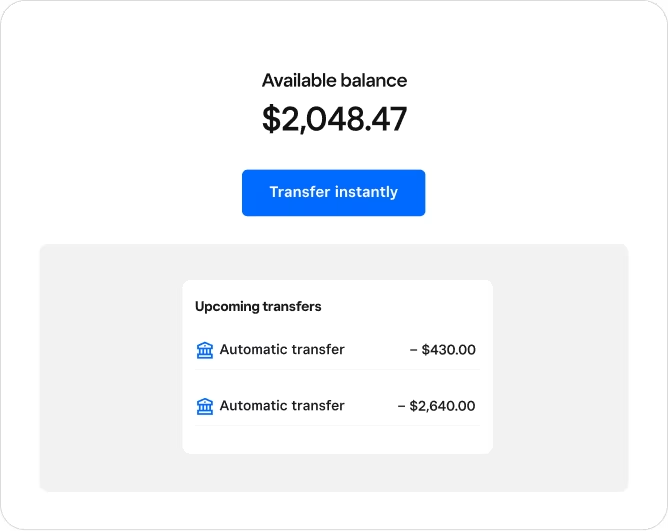

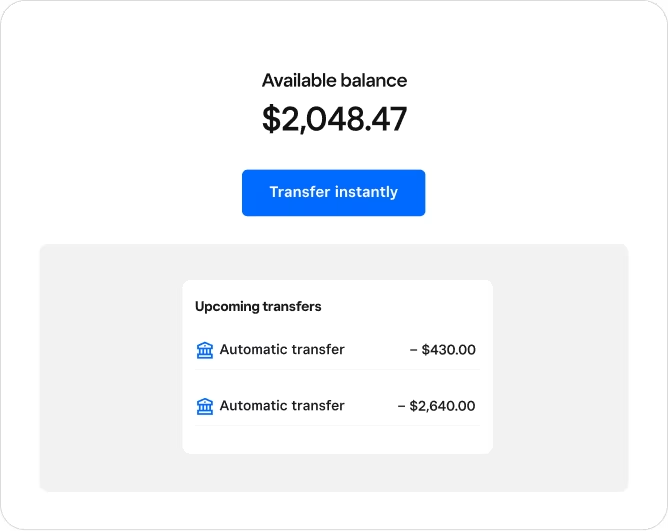

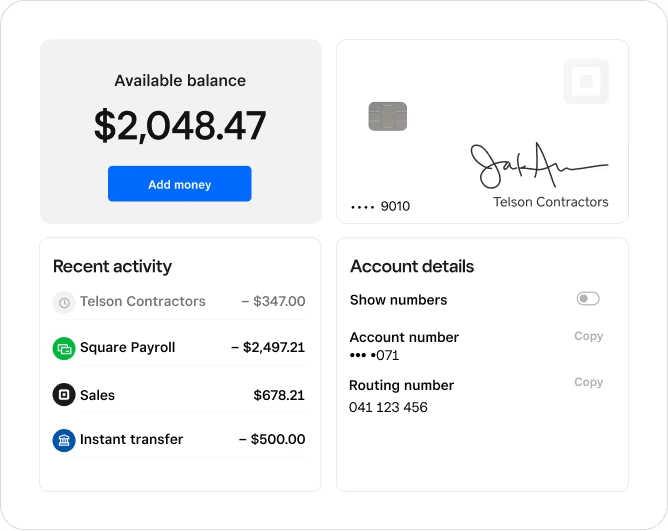

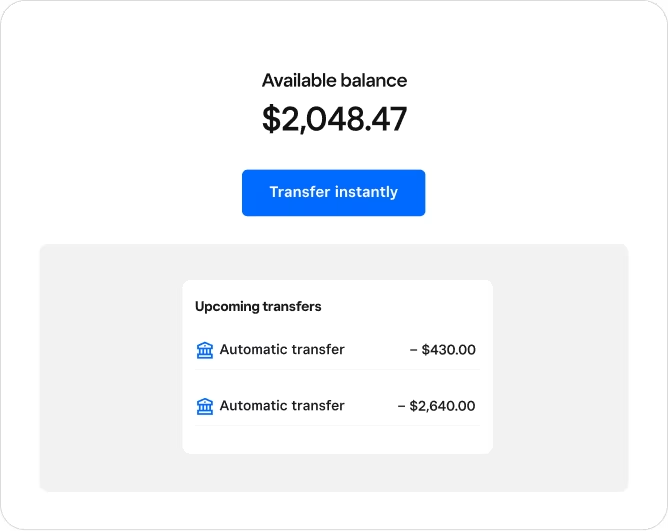

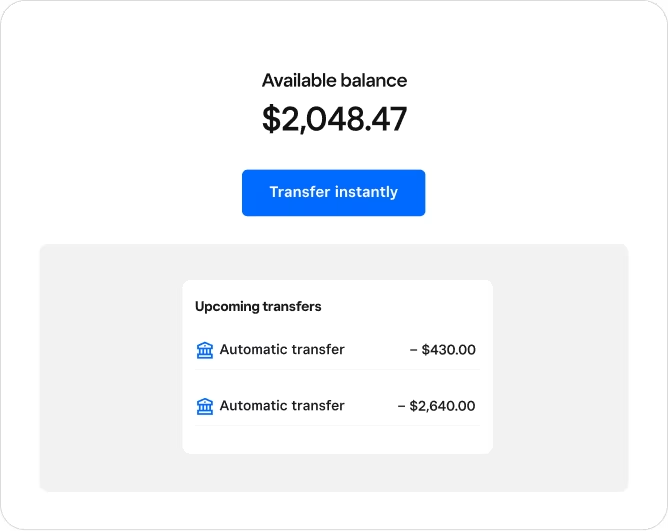

Improve cash flow with real-time tracking of receivables and payables, ensuring timely payments and financial stability.

Analyze detailed expenses related to materials, accessories, and production processes to identify cost-saving opportunities.

Combine production data with financial metrics for a comprehensive view of performance, supporting strategic planning and efficiency.

Ensures precise calculation of labor costs linked to production activities, enhancing budget management.

Minimizes errors in wage calculations by directly linking payroll data with production records, ensuring employees are paid correctly for their contributions. Fair, performance-based compensation increases employee engagement and efficiency, while detailed labor cost reports improve resource allocation for optimal workforce management.

Ensures employees are paid on time, maintaining high morale and productivity levels within the production team.

Offers insights into labor expenses, aiding in more accurate forecasting and budgeting for production activities.

Provides detailed labor cost reports that help in better allocation of workforce resources for production tasks.

Automates payroll processing, reducing manual data entry and freeing up HR staff to focus on production-related strategic tasks.

Keeps payroll processes aligned with current labor laws and tax regulations, reducing the risk of compliance issues.

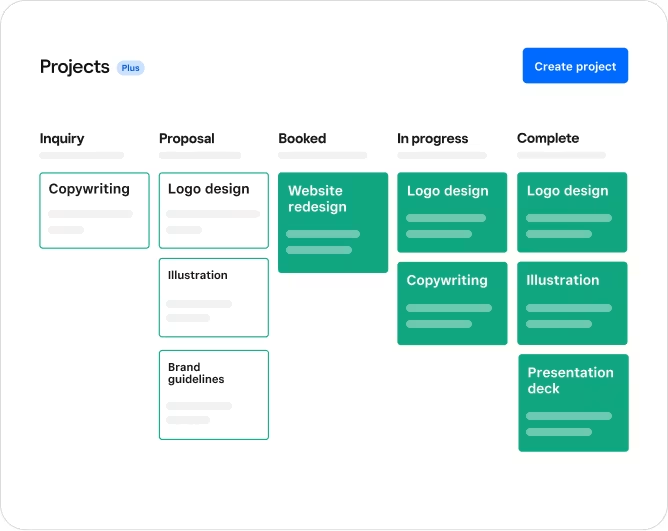

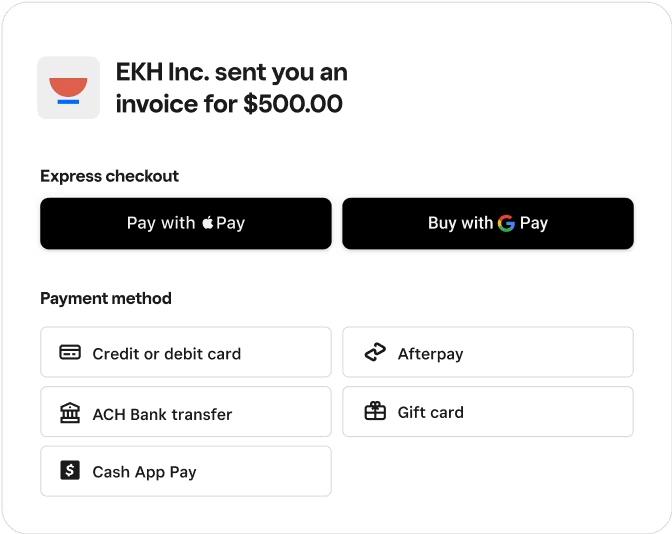

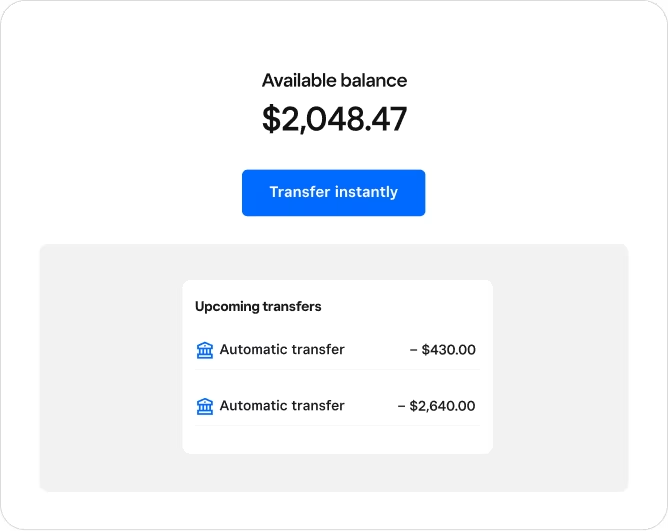

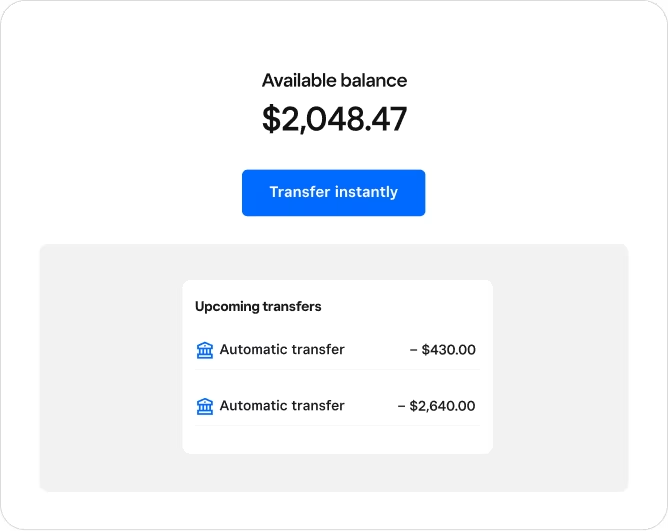

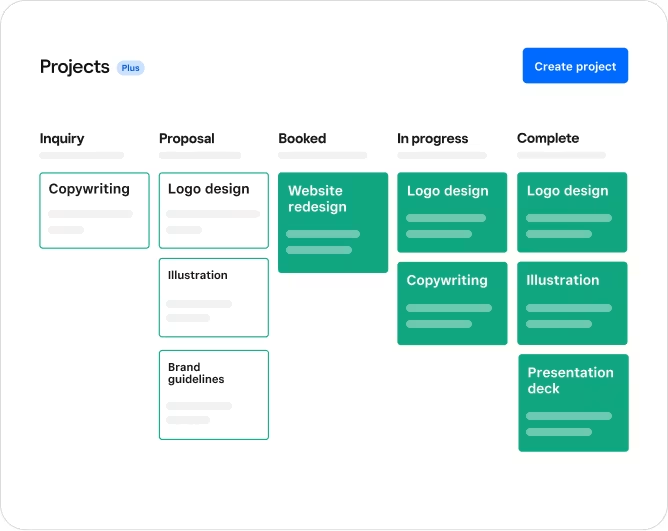

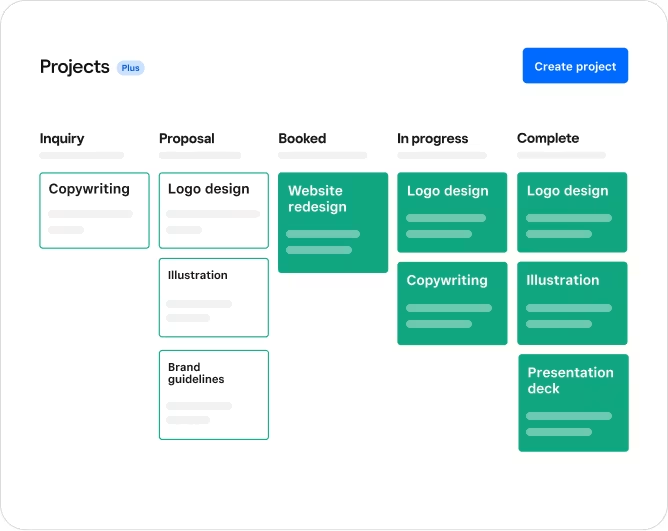

Sync sales and production data instantly to keep inventory accurate.

Minimize discrepancies between sales orders and production schedules.

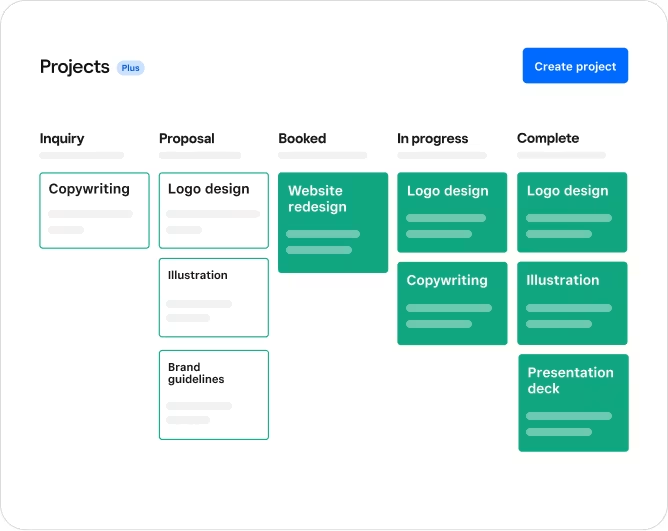

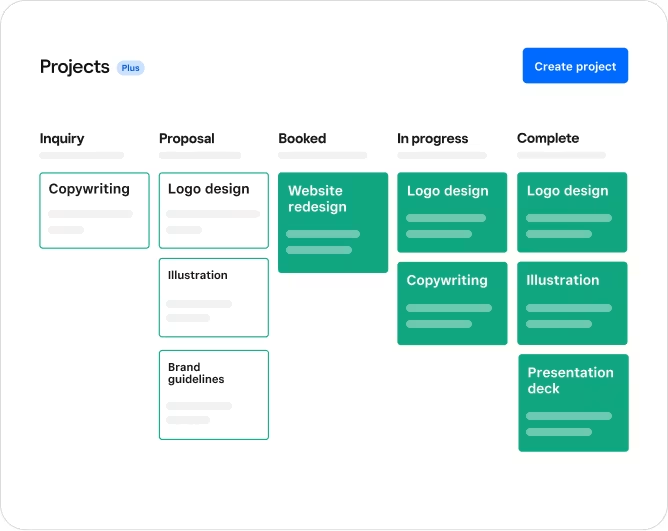

Streamline workflows and improve operational efficiency.

Access integrated data for informed decision-making and planning.

Integration refers to connecting our production software with other systems (like Timecare, Payroll HR, etc.) to enable smooth data exchange and coordination.

Benefits include:

Our software tracks yarn inventory by properties like yarn count, material, color, and fabric characteristics such as GSM. It also monitors work-in-progress (WIP) and manages yarn wastage to ensure accurate and efficient production.

Yes, you can oversee the distribution and receipt of materials required for dyeing, washing, and other production processes with our Production Issue/Receive feature. This ensures that all materials are accounted for and managed effectively.

Our software supports accurate fabric cutting and bundle barcoding. This feature enables you to handle fabric cutting processes precisely and implement barcodes for easy tracking and management of fabric bundles.

The Embellishment Issue/Receive feature streamlines the issuance and receipt of embellishments used throughout the production process, helping you manage these materials efficiently and accurately.

Our software provides comprehensive Inventory Reporting capabilities, including Inward, Outward, and Work-In-Progress (WIP) inventory reports. These reports offer detailed insights into your inventory status, aiding in precise inventory management.

Bundle Offline Management allows you to break down bundles into individual articles or pieces after completing all operations. This feature enables you to check, pack, and ship items by article, providing flexibility and efficiency in managing production bundles.

Packing Management helps you organize packing by color, size, and combination to ensure accurate order fulfillment. This feature streamlines the packing process and improves order accuracy.

Master Bundle Barcoding and Shipment facilitate the efficient barcoding of master bundles and tracking of shipments. This feature ensures that all bundles are accurately tracked from production to delivery.

Production Progress Reporting provides complete tracking of each Purchase Order (PO) across all stages of production. It allows you to monitor progress in detail, ensuring timely and efficient completion of each production phase.